E-commerce is slowly, but successfully changing the world around us. One day it will become an integral part of our life, and no one will remember how everything worked without it. Even today, such terms as e-trade, e-marketing, e-cash, and e-banking sound as entirely familiar concepts. The e-commerce industry is developing with startling speed and with the permanent improvements and innovations gains power every day. What are its main drivers? Which parts of this great mechanism are necessary for its existence? In 2013, Jack Ma, the Alibaba founder said that for all e-commerce firms three items are required for their growth and development. They are information flow, cash flow, and delivery. Is e-commerce nothing without delivery or can this component be neglected? Let’s consider the importance of efficient warehousing and transportation logistics, and evaluate whether they refer to critical success factors or not.

Delivery Innovations. Step Forward From the Usual Technologies

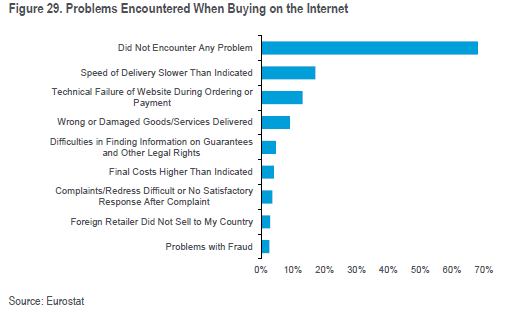

The strict rise of e-commerce, especially its e-trade part, and its penetration into our everyday life has resulted in the occurrence of new problems never known before. Demand for small parcel deliveries has grown dramatically because of the increased popularity of online shopping, and the delivery problem has confidently occupied the top place among the main issues encountered when buying on the Internet.

Delivery companies all around the world are struggling to keep pace and more than 20{3fbfd6f1e6b19884051837dbbbebf333964dd5fac151615ffbd47b80e5ecc87a} of customers claim that delivery speed is slower than indicated by the seller. Research was conducted in order to solve this problem and several developments in delivery technologies were offered.

What could we do to “kill two birds with one stone” – keep pace with the rising popularity of online shopping and increase the delivery speed?

- Trucks stuck in traffic cost companies $28 million annually. Among possible options to solve this problem is installing the unique signals prioritizing trucks along freight corridors, as well as providing truckers with the real-time information about truck routes.

- More than 50{3fbfd6f1e6b19884051837dbbbebf333964dd5fac151615ffbd47b80e5ecc87a} of operating expenses refer to the parcel industry. Even though the parcel delivery is standardized good enough, human resources still play a decisive role in this sector. All the conventional delivery vehicles are loaded manually and driven by the delivery personnel. Then, the driver has to carry the parcels to the front door and hand to the consignee personally. The potential solutions to this problem include using drone technology. It may shorten the human resources, but the current drones can carry only one package, and after delivery have to return to the base to recharge the batteries and pick up the next parcel. If the number of drops and the parcels per drop will increase in the future, the drones have all chances to replace humans in the parcel industry.

- Increased flexibility of parcels delivery with self-driving cars. According to the DPD research, it may be possible to deliver a part of parcel volumes using the self-driving vehicles, but the legal framework for the application allowing to perform it, will be available only after 2025 and this is the earliest term. There are five potential ways to use autonomous delivery vehicles:

- Delivery of the parcels to the consignee;

- Autonomous parking in the center of the city;

- Independent mini transporters in the city center;

- Mobile pickup stations throughout the city;

- Consignees control the time and place of self-driving vehicles via the app.

- Shipping platform for linking ships with trucks and drivers. A new Uber-like shipping platform is testing in China that allows access to the pool of urban drivers providing them with all details of delivery. The application offers pricing information, a trip planner, and the route map to help drivers maximally improve the terms of delivery. It also provides them with information about suggested pickup sites and even optimizes load according to the size of the vehicle. If other services like unpacking or installation are undertaken, it will also be mentioned in the app. The application allows to avoid canceled orders and can help to reduce fleet costs by 30{3fbfd6f1e6b19884051837dbbbebf333964dd5fac151615ffbd47b80e5ecc87a}.

Warehouses. Global Challenges and Solutions

According to the DHL report, the whole spectrum of the warehouses available for today goes from one large central hub to the localized fulfillment. Both these types have challenges, although each of them is necessary for efficient and fast delivery. For example, storage of slow turning stock keeping units (SKUs) in the local fulfillment center is quite costly, but shipping items that should be delivered within hours rather than days are impossible without these centers.

Analytics noticed a significant rise in cross-border e-commerce was accounted recently. According to Eurostat researches, the percentage of online sellers in the EU offering products from outside the EU remains minor but has increased from 13{3fbfd6f1e6b19884051837dbbbebf333964dd5fac151615ffbd47b80e5ecc87a} (in 2012) to 20{3fbfd6f1e6b19884051837dbbbebf333964dd5fac151615ffbd47b80e5ecc87a} (in 2016). The cross-border e-commerce is expected to grow 25{3fbfd6f1e6b19884051837dbbbebf333964dd5fac151615ffbd47b80e5ecc87a} annually until 2020 that is almost twice the rate of domestic e-commerce. What does it mean? It is much more profitable financially to ship orders cross-border than having slow-turning SKUs in the local fulfillment centers.

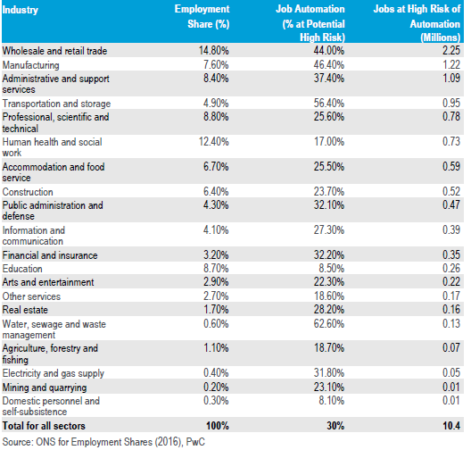

The whole delivery process is changing nowadays. With e-commerce development, warehouses become more and more automated, the delivery process requires less human resources to be faster and more efficient, and global integration and technology impact on labor significantly. IMF concludes that for all the advanced economics technology remains the most significant contributor to changes in labor shares. What are the main risks for jobs in retailing and storage? Successful e-commerce and automation go hand in hand, and the automation impact on retailers, warehousing, and delivery can’t be neglected. According to the PWC report, jobs in the Transportation & Storage industry are at the highest risk of automation (56{3fbfd6f1e6b19884051837dbbbebf333964dd5fac151615ffbd47b80e5ecc87a} of jobs by 2030). The Transportation & Storage sector includes not only transportation activities but also Warehousing & Support Activities as well as Postal & Courier Activities. Labor is not only at the high risk of automation, but it is also considered as a factor that slows down the e-commerce development and growth for warehouse brokers and property owners.

Nevertheless, warehousing remains a significant user of labor. Why is it and what advantages can it bring to the delivery? In some cases, the agility, hand-eye coordination, and flexibility of humans can’t yet be replaced with the machines. Commercially viable automated picking in unstructured environments remains a difficult challenge. It is the main reason of Amazon Robotics Challenge that focuses on combining academic and industrial know-how to improve warehouse picking technologies maximally. According to the survey for Modern Materials Handling, over the next three years, labor availability will be one of the three most important issues. It means that for warehouse automation, the most significant changes and challenges for labor are still yet to come.

Faster, Simpler, Better. Perspectives of Warehouse Automation

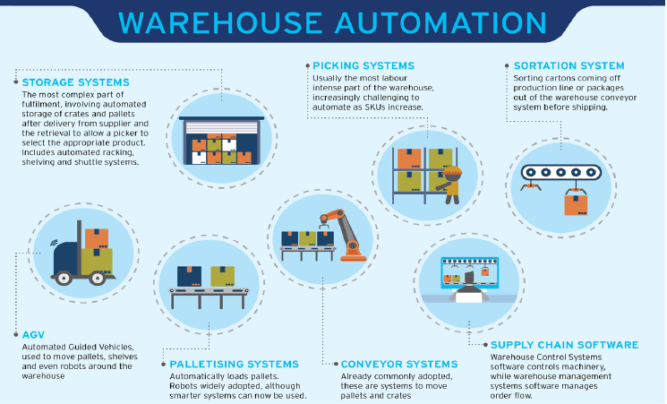

We have already mentioned that warehouse automation is going to cause a significant impact on labor and is an integral part of e-commerce development. But what is it? It is a catch-all term which includes sortation systems, picking systems, conveyors, retrieval systems, and palletizing systems. Let’s consider all of these terms separately.

- Picking systems. In many cases, picking is the most labor intensive part of the fulfillment center. Automated storage and retrieval systems are created for bringing the goods to the picker, significantly speeding up the process. In addition to this, such technologies as pick-to-light and pick-to-voice can increase the efficiency of work even if the process isn’t fully automated.

- Automated sorting. Systems are used for sorting cartons coming off the production line before shipping. Sortation systems are well-adapted for small parcels.

- Palletizing systems. In all the warehouses the standard pallets are used for goods. The main task of palletizing systems is to load these pallets automatically.

- Automated retrieval and storage systems. It is the most complicated part of the warehouse automating. The systems are necessary for storage of pallets and crates after delivery from the supplier and allow picker to select the appropriate good. They also include automated shuttle, shelving, and racking systems.

- Warehouse management systems. It is the unique software supporting and integrating all the automated processes in the warehouse.

Conclusion and Highlights

Taking into account everything reviewed, we can state the following:

- Efficient, fast, and innovated delivery is an integral part of the e-commerce growth for today;

- The more attention is given to the crucial delivery and warehousing problems, the faster will be the e-commerce development.

- Jobs in Transportation & Storage industry are at the highest risk of automation;

- A lot of innovations have already been involved, but there are still some critical challenges slowing down the delivery process.

E-commerce penetration in our life is rising rapidly, and this dramatically changes many industries related to it. The usual way of life will not be the same in twenty, fifty years, as the newest innovations are devoted to making our lives better and more straightforward.

Recent Comments